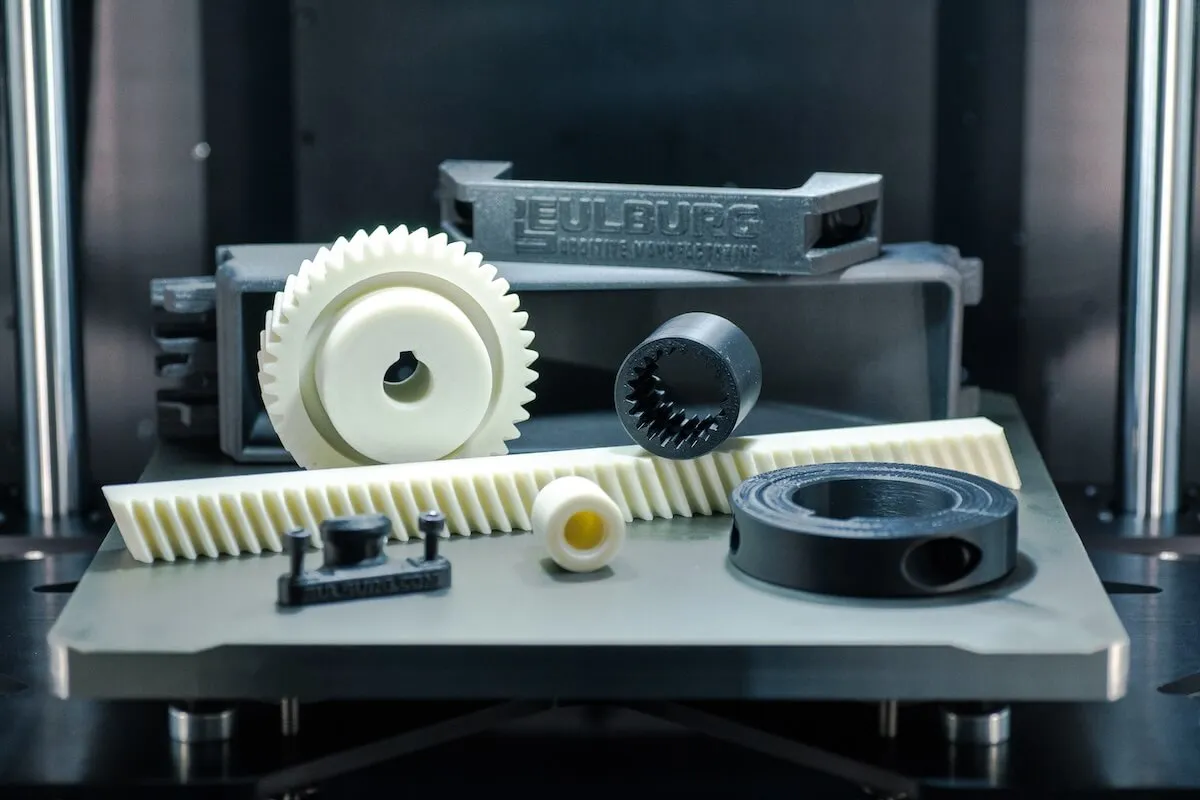

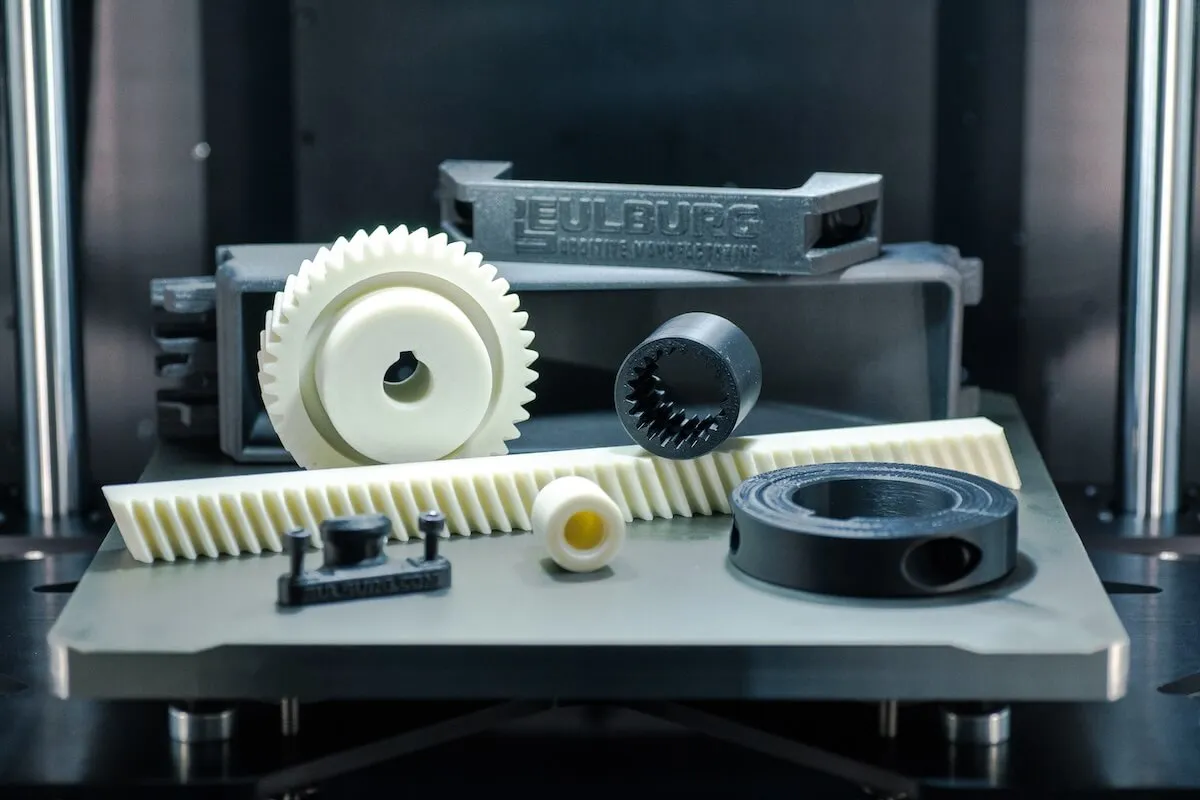

3D Printing.

Strong Results.

Built on injection-molding expertise and polymer science, we manufacture production-grade parts that are reliable, repeatable, and efficient. Where material, process, and performance align.

Core Capabilities & Services

Industrial additive manufacturing with local expertise and proven industry standards.

Reliable, High-Performance Parts

Strong, precise, repeatable parts to meet demanding industrial requirements – with no minimum order quantity.

Adaptive Scheduling

Flexible production planning to meet your project timelines efficiently.

On-Site Technical Support

Direct, hands-on assistance for integration and problem-solving.

Transparent Communication

Clear updates, predictable deliverables, and proactive project communication.

Rapid Turnaround Focus

Guaranteed rapid turnarounds for urgent needs.

Scalable Capacity

Build capacity designed to accommodate your prototyping and production growth.

Local on-site consultation, support, and troubleshooting – standard in the DFW Metroplex.

Industrial-Grade Compounds

Selecting the right material is critical. LUVOCOM® 3F compounds form the backbone of our material platform — delivering engineered performance and repeatable production quality for industrial additive manufacturing.

Core Materials – Proven Reliability

PET CF 9780 BK

LUVOCOM® 3F high-performance compounds – exclusive U.S. distribution through EULBURG

- Tensile Strength (XY)

- 85 MPa

- Flexural Modulus

- 9.18 GPa

- Heat Deflection (@1.80MPa)

- 156 °C

- Critical

- >1×10¹² Ω

Details: Tensile [XY/ZX]: 85 / 31 MPa (ISO 527-2); Flexural: 127 MPa, 9.18 GPa (ISO 178); Impact: 11 kJ/m² (ISO 180); HDT @ 0.45 MPa: 205°C (ISO 75); Volume / surface resistivity: 1×10¹¹ / >1×10¹² Ω (EN 62631); Moisture uptake: <0.3% (ISO 62); Density: 1.4 g/cm³ (ISO 1183); Stiff and strong, Temperature resistant, Chemically resistant, Excellent surface quality

PPS CF 50899 BK

LUVOCOM® 3F high-performance compounds – exclusive U.S. distribution through EULBURG

- Tensile Strength (XY)

- 75 MPa

- Flexural Modulus

- 6.75 GPa

- Heat Deflection (@1.80MPa)

- 233 °C

- Critical

- UL94 V0, >1×10¹² Ω

Details: Tensile [XY/ZX]: 75 / 46 MPa (ISO 527-2); Flexural: 129 MPa, 6.75 GPa (ISO 178); Impact: 15 kJ/m² (ISO 180); HDT @ 0.45 MPa: 239°C (ISO 75); Continuous use: 220°C; Volume / surface resistivity: 1×10¹¹ / >1×10¹² Ω (EN 62631); Moisture uptake: <0.05%; Density: 1.48 g/cm³ (ISO 1183); Stiff and strong, High temperature resistance, Excellent chemical resistance, UL94 V0, Cost-effective PEEK alternative

PAHT 9936 BK/L

LUVOCOM® 3F high-performance compounds – exclusive U.S. distribution through EULBURG

- Tensile Strength (XY)

- 67 MPa

- Flexural Modulus

- 2.24 GPa

- Heat Deflection (@1.80MPa)

- 90 °C

- Critical

- Food Compliant, Detectable

Details: Tensile [XY/ZX]: 67 / 30 MPa (ISO 527-2); Flexural: 88 MPa, 2.24 GPa (ISO 178); Impact: 154 kJ/m² (ISO 180); HDT @ 1.80 MPa: 90°C (ISO 75); Continuous use: 100°C; Moisture uptake: <1.5% (ISO 62); Density: 1.25 g/cm³ (ISO 1183); Strong and tough PA, Temperature resistant, Chemically resistant, Food Compliant, Detectable

Specialty Materials

Our core LUVOCOM® 3F compounds cover the vast majority of use cases. Through our Polymer Selection Consulting, we help identify the most suitable material for your application.

For applications requiring strict regulatory properties — such as UL94 V-0, EN 45545-2 rail compliance, NORSOK M710 (oil & gas), ESD-safe electrical conductivity, or safety-critical color coding — we offer dedicated material solutions.

Trusted quality

and strength for

your needs.

Local expertise

with industry

standards.

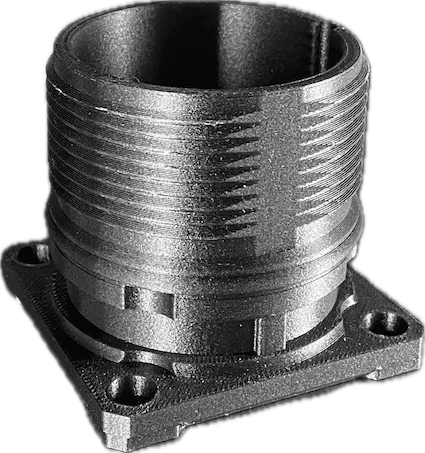

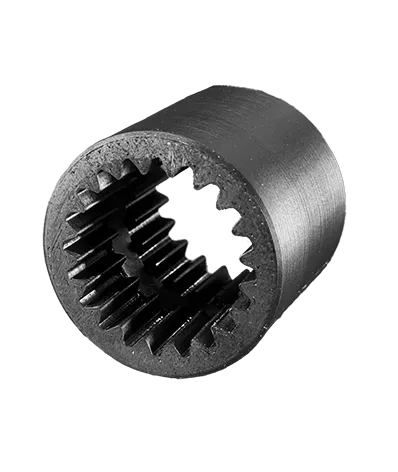

Additive → Injection Molding → Aftermarket

We enable a seamless production path — from additive low- and mid-volume manufacturing into injection molding, and back into additive for aftermarket supply. With material twins, we provide injection molding compounds with performance levels closely matched to their additive counterparts.

Qualified Printers for Internal Validation

We offer qualified 3D printers pre-configured for our LUVOCOM® 3F core materials, enabling customers to perform internal part validation on the same material base used later for series production through EULBURG. As the exclusive U.S. distributor of LUVOCOM® 3F filaments, all materials are supplied directly through us.

Key Industrial Applications

Prototyping, tooling, and production parts for demanding industrial environments.

Prototyping & Production

Rapid prototyping, short-run production, batch manufacturing.

Tooling & Fixtures

Jigs, fixtures, housings, nests, alignment tools, inspection tools, custom production aids.

End-Use Components

Durable parts for operational environments — strong, stable, and repeatable under real loads.

Labeling & Marking

Labels, part marking, serial numbers, barcodes, QR codes.

Special Components

ESD-safe, flame-retardant, radiation-attenuating, food-compliant, safety-coded, or detectable parts.

Applicable Across

Aerospace & Defense, Automotive, Oil & Gas, Energy, Electronics, Chemical Processing, Industrial Equipment, and related sectors.

Precision Engineering Meets Local Collaboration

"From concept to completion, you receive hands-on support, transparent communication, and reliable results."

Eulburg Additive Manufacturing, rooted in German precision engineering, delivers strong printing solutions with direct technical collaboration to efficiently deliver your industry goals.

Felix Jackson

Founder & Managing Member

Plastics Processing Expert – 3D Printing & Injection Molding

(German IHK-certified apprenticeship – Injection Molding)

Let’s Connect & Discuss Availability

We offer direct technical consultation to help you identify the right materials and develop a reliable production path for your project.

Felix Jackson

Founder & Managing Member